How to Make a Handpan in 6 STEPS

Inquistive muscians, engineers, metal workers, hobbyists and makers who have heard the sound of handpan music- all inevitably seem drawn to ask the question, ”How do you make a handpan?”

The exterior shape offers few answers. With two steel sheets of metal fastened together to look much more like a UFO or a weber grill, the hammer marks and dimples hint at something beyond the visible form. For the piano, we can lift the lid and see the felt tipped hammer that strikes the strings, for the drum we can see the mallets or hands bounce upon a stretched membrane, for the woodwind we can find the reed and sounding holes.

But with handpan instrument, we hear evidence of mechanism, yet look inside to find only a hollow body…It is this new form and sound that has captured our attention.

Every handpan builder employs different steps to reach their unique sound. The recipes get more refined and specific over time. Below are a few pictures which share a very basic process of building a handpan. Click on the pictures for more information. For more technical & in depth resources for those looking to try their hand at building, we recommend this handpan building page by Saraz handpans and this building resources page at Handpan Makers United.

We StarteD DIY Handpan Building back in 2011…

We’ve come a long way. Here’s a little more, about being a Maker.

I hope this inspires you! - Jenny

Step 1. Sinking. Transforming a flat steel surface into a bowl shape that will eventually become a handpan.

Step 2. Shaping the handpan. All makers use different tools, including many different custom hammers for this process.

Step 3. Heat treatments. Methods we use may include torches, kilns, ovens or furnaces.

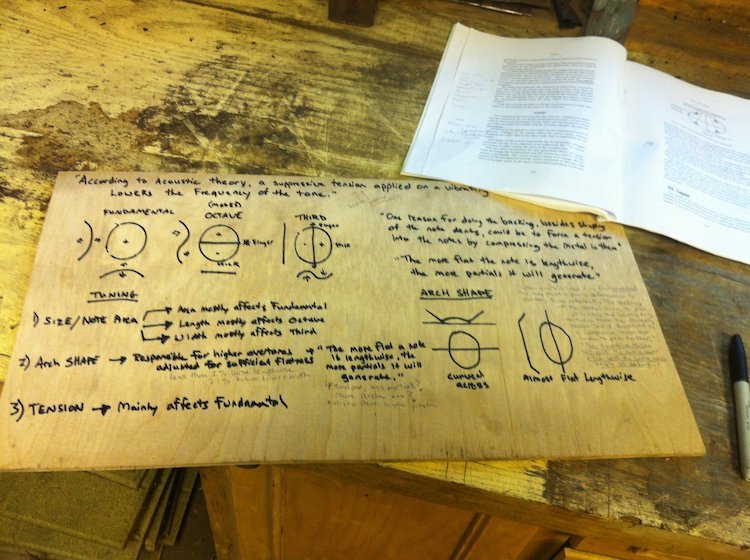

Step 4. Tuning. Differentiation in instrument timbre, sound and stability all come from the variations in these processes.

Step 5. Glueing. Most handpans are joined with adhesives choosen by the builders.

Step 6. Retune(s) after glue. Once the shells are joined, the handpan builder retunes the instrument through the soundhole with a small hammer.

Do You have a Passion For Building Handpans & want to be Part of our Team?

We encourage you to reach out and see what positions we have available.